Reaction Bonded Silicon Carbide (RBSiC): A Pinnacle of Engineering Innovation

In the realm of advanced materials, Reaction Bonded Silicon Carbide (RBSiC) stands as a paragon of technological progress and engineering prowess. This extraordinary compound has revolutionized numerous industries, offering a unique confluence of exceptional mechanical properties, chemical resilience, and thermal stability. Here, we delve into the unparalleled attributes and multifaceted applications of RBSiC, illustrating why it is an indispensable choice for demanding environments.

The Genesis of RBSiC

Reaction Bonded Silicon Carbide is synthesized through an ingenious process that combines silicon carbide (SiC) powders with free silicon in a high-temperature environment. During the reaction bonding process, molten silicon infiltrates the porous SiC structure, creating a dense, near-net-shape material with minimal dimensional distortion. This meticulous fabrication method endows RBSiC with a distinctive microstructure that underpins its superior performance characteristics.

Exceptional Properties of RBSiC

Mechanical Robustness

RBSiC exhibits remarkable hardness and wear resistance, making it a preferred material in high-abrasion scenarios. Its superior mechanical strength is retained even at elevated temperatures, ensuring reliability in extreme conditions.

Thermal Stability

The material’s outstanding thermal conductivity and low thermal expansion coefficient render it highly resistant to thermal shock. This trait is crucial in applications involving rapid temperature fluctuations.

Chemical Inertness

RBSiC’s inertness to a broad spectrum of corrosive agents, including acids, alkalis, and molten salts, ensures longevity and durability in chemically aggressive environments.

Dimensional Precision

The near-net-shape manufacturing process facilitates the production of components with precise geometries, reducing the need for post-processing and enhancing overall efficiency.

Multifaceted Applications

The versatility of Reaction Bonded Silicon Carbide finds expression across a diverse range of industries:

Aerospace and Defense: RBSiC components are integral in spacecraft thermal protection systems and high-performance nozzles, where material integrity under extreme thermal and mechanical loads is non-negotiable.

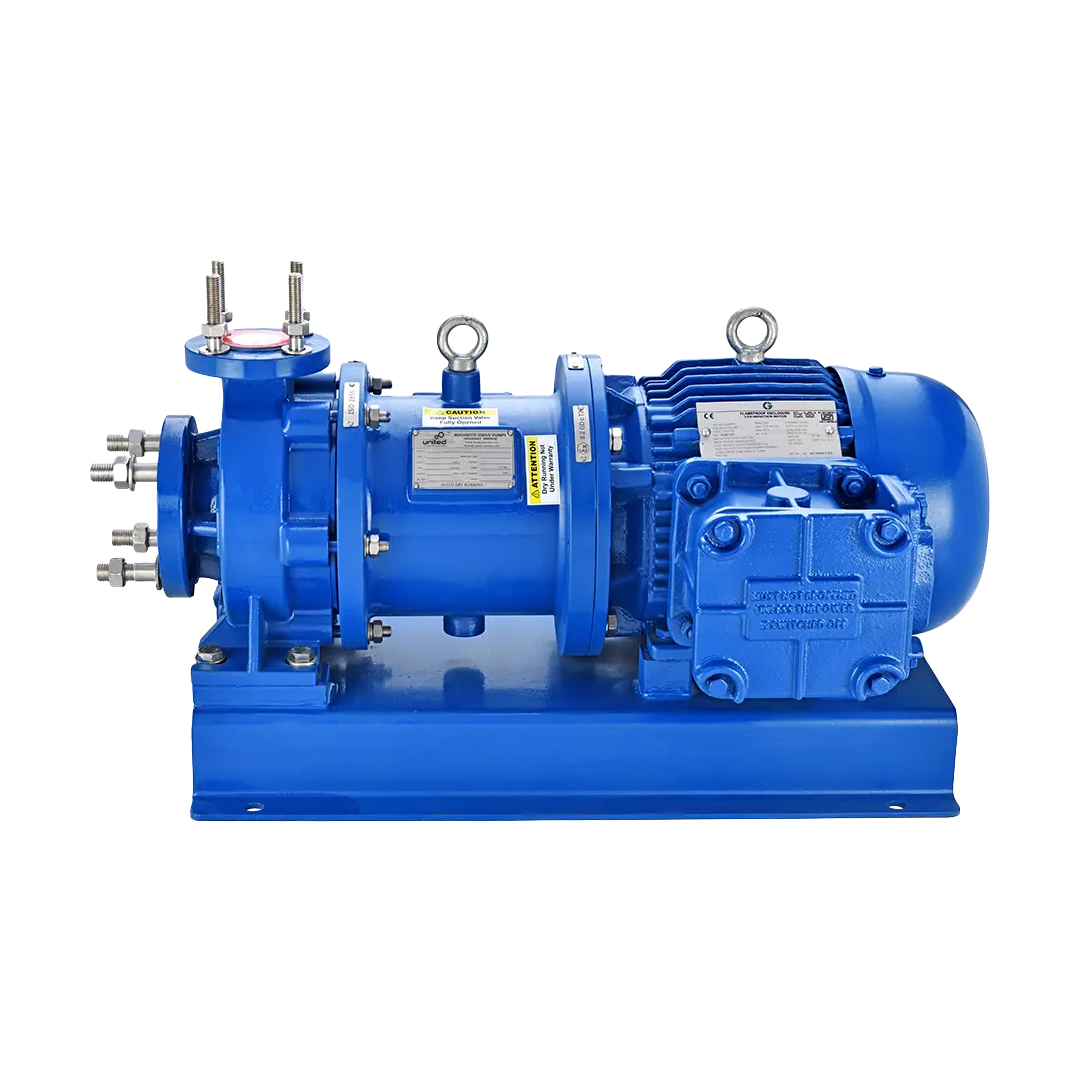

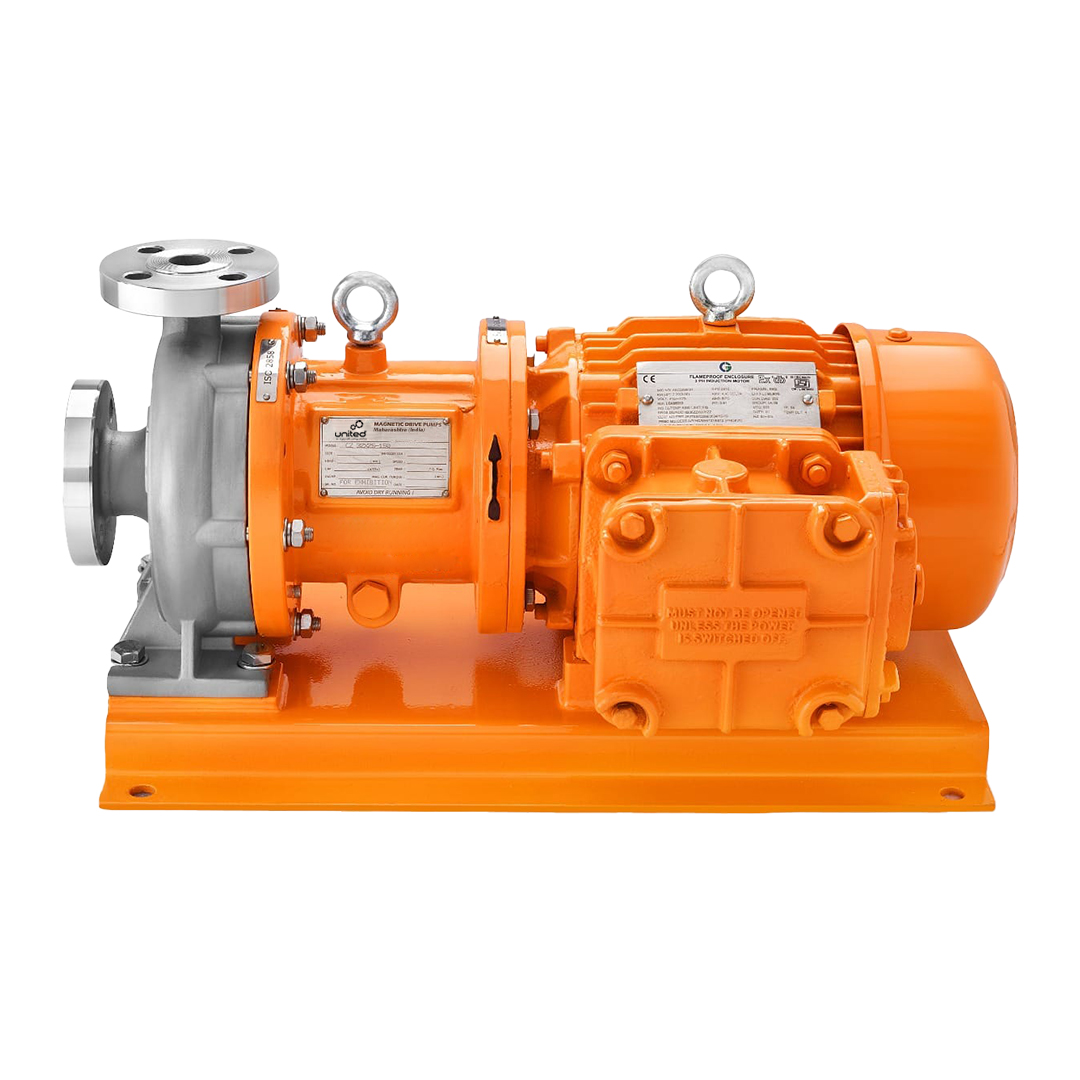

Industrial Machinery: Bearings, seals, and pump components crafted from RBSiC excel in high-wear and high-corrosion environments, significantly extending service life and reducing maintenance costs.

Energy Sector: In power plants and renewable energy systems, RBSiC is utilized for heat exchangers and burner nozzles, capitalizing on its thermal and chemical resilience.

Semiconductor Industry: RBSiC’s dimensional stability and chemical inertness make it an ideal choice for wafer carriers and process chamber components in semiconductor fabrication.

A Material for the Future

As industries pivot towards higher efficiency and sustainability, Reaction Bonded Silicon Carbide continues to be at the forefront of material science innovation. Its ability to withstand the rigors of modern industrial demands while maintaining unparalleled performance underscores its irreplaceable role in the engineering landscape. Conclusion

Reaction Bonded Silicon Carbide is not merely a material; it is a testament to human ingenuity and the relentless pursuit of excellence. Its exceptional properties and versatile applications position it as a cornerstone of modern engineering solutions. For enterprises seeking reliability, precision, and longevity, RBSiC represents the zenith of material technology. By investing in RBSiC, industries not only embrace advanced material science but also pave the way for a future defined by resilience and innovation.