Wave Spring: A Compact and Efficient Alternative to Traditional Springs

A wave spring is a type of compression spring designed with multiple waves in its structure, allowing it to provide the same force and deflection as conventional coil springs but in a significantly reduced space. Unlike traditional coil springs, wave springs offer a more compact and lightweight solution while maintaining high load-bearing capabilities.

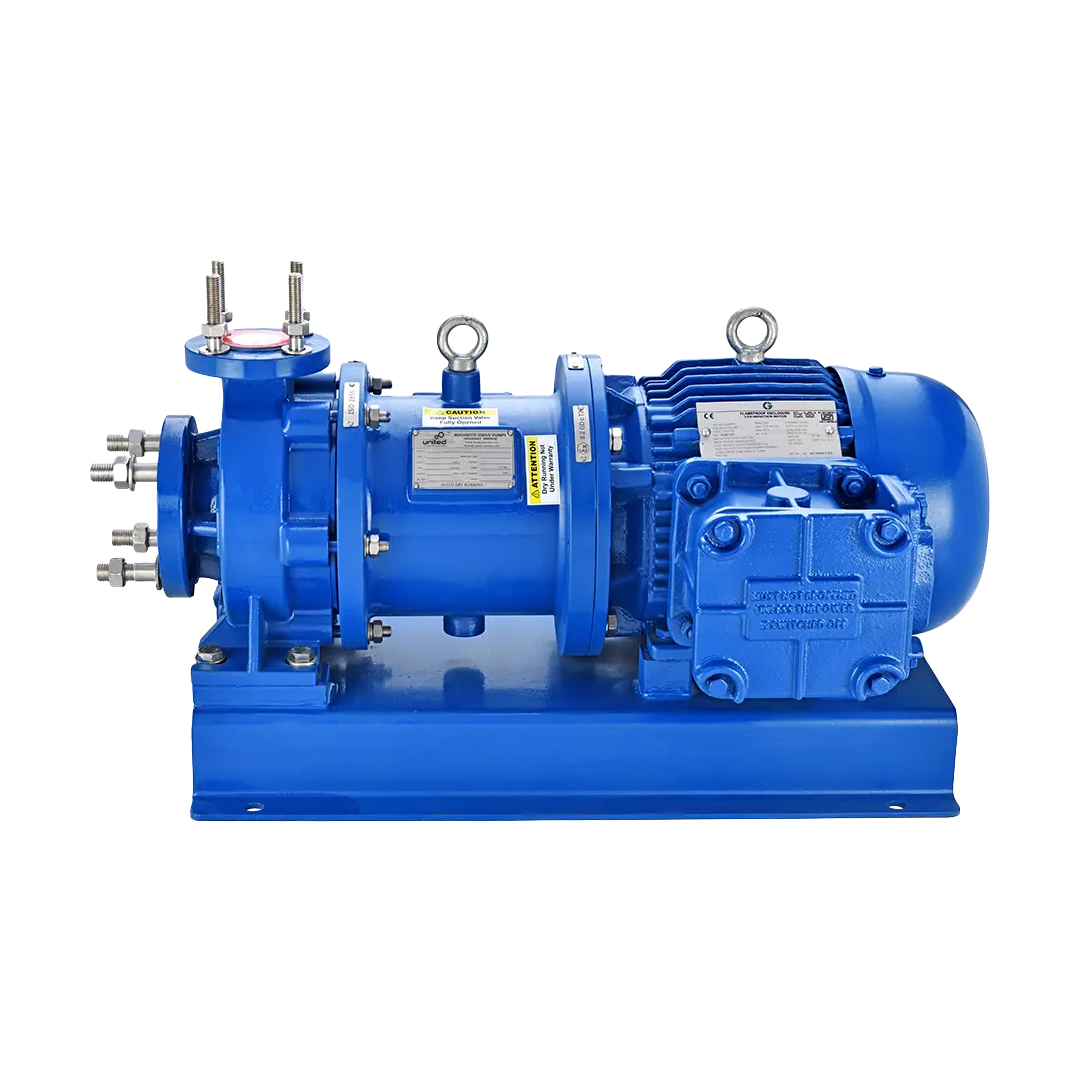

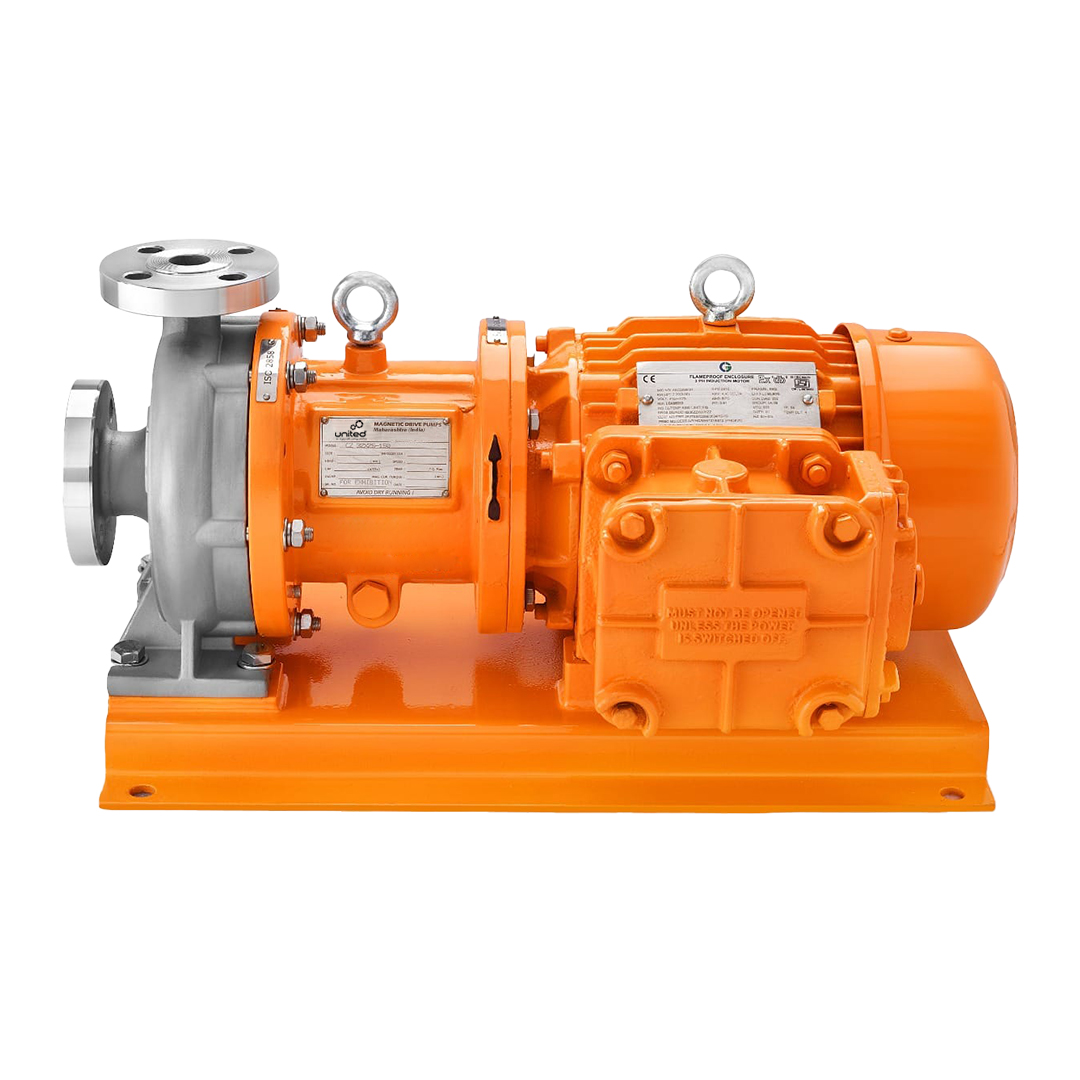

Wave springs are widely used in mechanical seals, pumps, aerospace components, automotive systems, and medical devices due to their space-saving design and efficient performance. They are typically manufactured from high-quality materials such as stainless steel, Inconel, and other corrosion-resistant alloys to withstand harsh environments and demanding applications.

Advantages of Wave Springs

-

Space-Saving Design

- Wave springs provide the same force output as conventional coil springs but with up to 50% reduction in height.

- Ideal for applications where minimizing space is crucial, such as compact machinery and precision instruments.

-

Lightweight and Material Efficient

- Uses less material than traditional springs, making it a cost-effective and lightweight alternative.

- Particularly beneficial in industries like aerospace and automotive, where weight reduction enhances efficiency.

-

High Load Capacity with Compact Structure

- Despite their smaller size, wave springs can handle significant loads, making them suitable for high-performance applications.

-

Consistent and Precise Force Output

- Provides uniform load distribution, ensuring smooth and reliable operation in mechanical systems.

- Helps maintain constant pressure in sealing applications, improving efficiency and longevity.

-

Reduced Vibrations and Noise

- The wave-like design helps absorb shock and vibrations, leading to quieter and smoother performance.

-

Customization for Specific Applications

- Available in various materials, configurations, and dimensions to meet industry-specific needs, including high-temperature and corrosive environments.

-

Energy Efficiency and Longevity

- Reduces internal friction and stress, leading to longer operational life and lower energy consumption in mechanical systems.

Wave springs have revolutionized the way engineers design compact, high-performance mechanical systems. Their ability to provide efficient load-bearing capacity while reducing space and weight makes them an essential component in modern industrial applications.