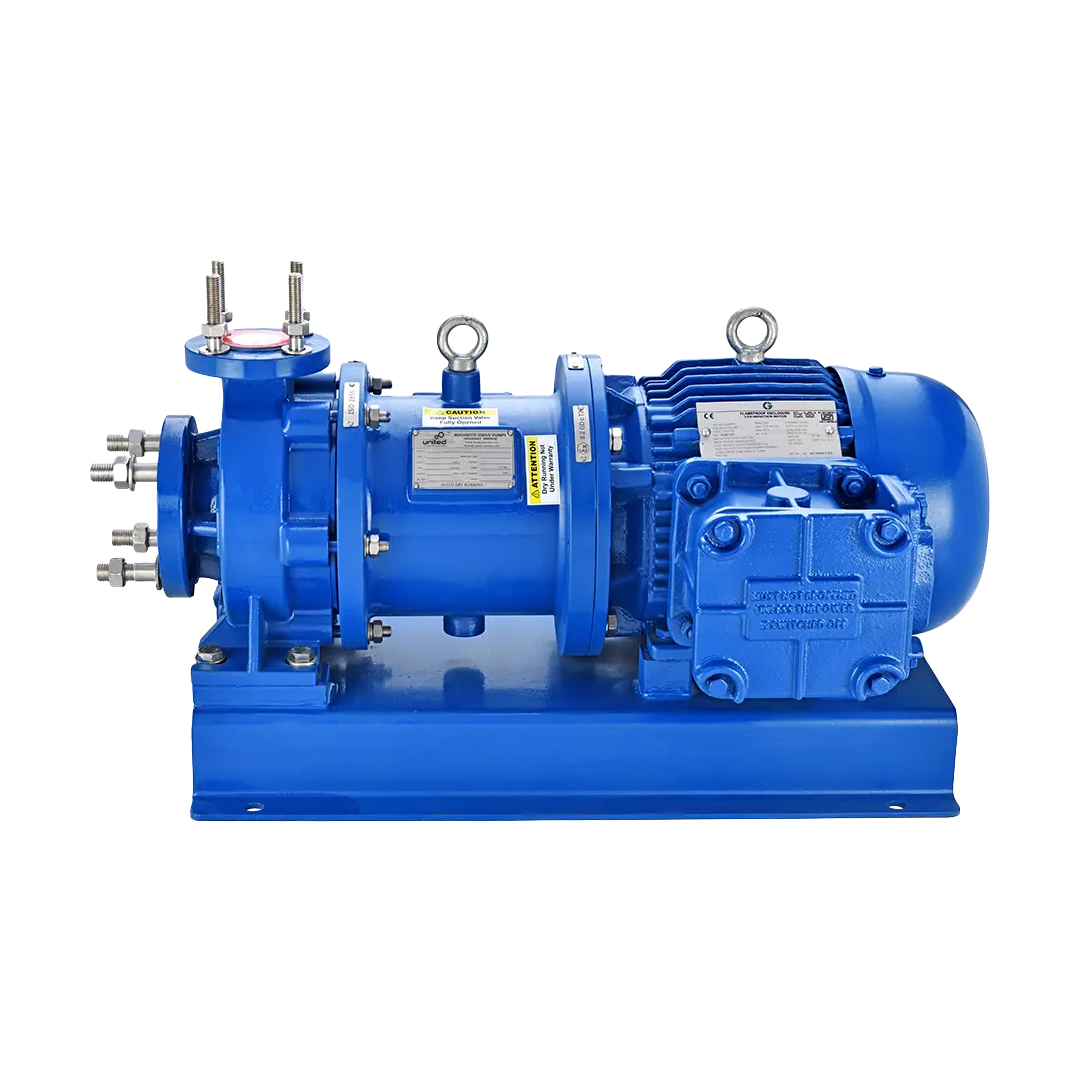

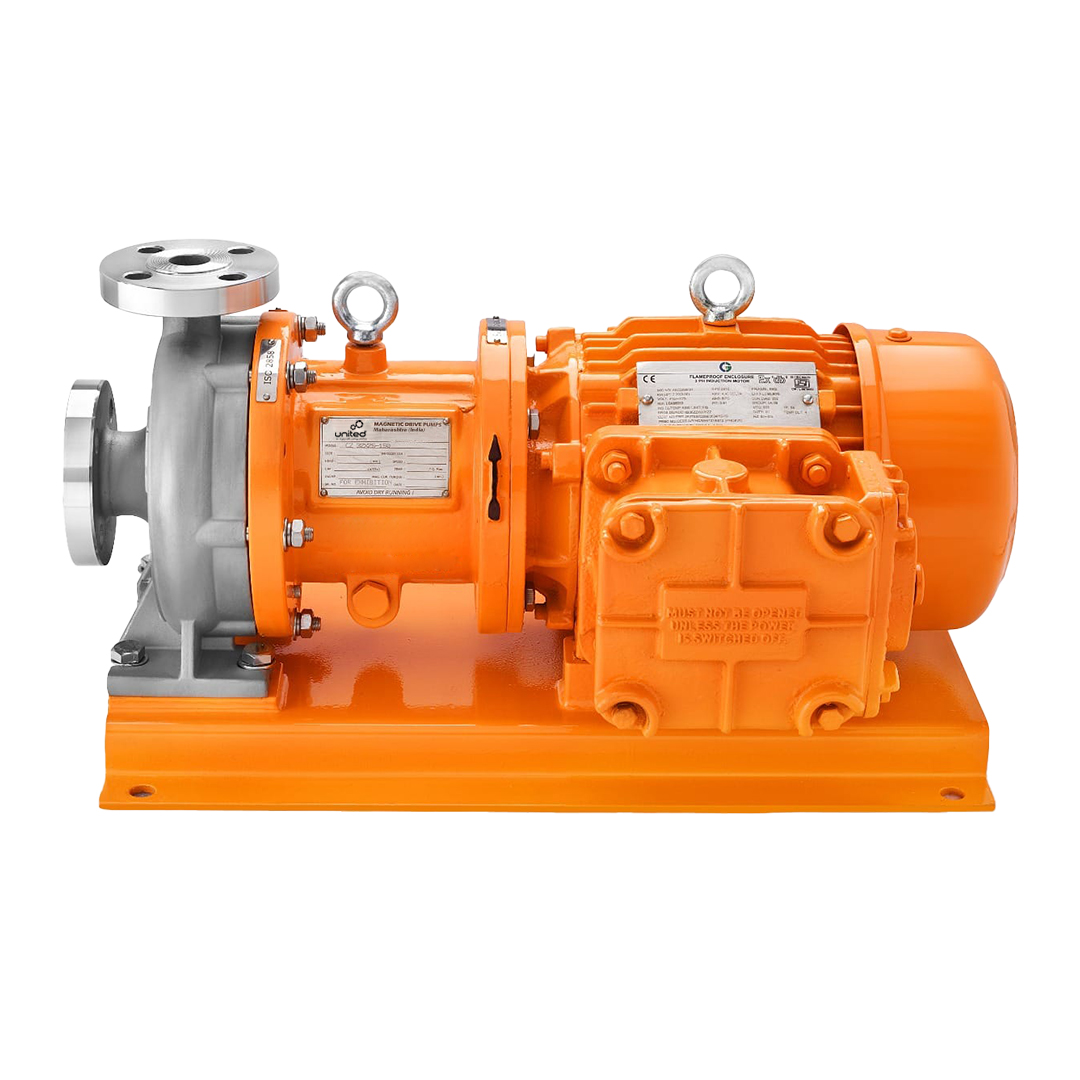

In the world of industrial fluid handling, magnetic drive pumps (also known as mag-drive pumps) have become a preferred choice for transferring aggressive, hazardous, and high-purity liquids—particularly in applications where leakage must be avoided at all costs. But what exactly are magnetic drive pumps, and how do they operate? Let’s explore their working principles, design advantages, and typical applications in detail.

Understanding Magnetic Drive Pumps

Magnetic drive pumps are a type of sealless centrifugal pump that use magnetic coupling instead of a traditional mechanical shaft seal to transfer torque from the motor to the impeller. This design eliminates the dynamic seal—the primary source of leakage in standard pumps—making magnetic drive pumps a safer and more reliable solution in critical applications.

How Do Magnetic Drive Pumps Work?

1. Magnetic Coupling Mechanism

At the heart of the pump is a dual magnet assembly:

-

Outer Drive Magnet: Connected to the electric motor shaft.

-

Inner Drive Magnet: Attached to the impeller inside the sealed pump chamber.

When the motor turns the outer magnet, it magnetically locks with the inner magnet, causing the impeller to rotate and move fluid through the system—without any physical contact between the drive shaft and the impeller.

2. Sealless Pump Chamber

The pump housing is fully sealed by a containment shell or rear casing—commonly made of PFA-lined, stainless steel, or engineered polymers—ensuring that the pumped fluid remains isolated from the external environment.

3. Centrifugal Force Operation

Like conventional centrifugal pumps, mag-drive pumps generate flow and pressure through centrifugal force as the rotating impeller imparts velocity to the fluid. This combination of sealless technology with centrifugal pumping principles provides both performance and safety.

Key Advantages of Magnetic Drive Pumps

-

Zero Leakage: No mechanical seal means zero risk of seal failure and hazardous fluid leakage.

-

Reduced Maintenance: Fewer moving parts result in lower maintenance costs and longer service life.

-

High Chemical Resistance: Ideal for corrosive and toxic fluids (e.g., acids, solvents, hydrocarbons).

-

Energy Efficient: Modern designs optimize hydraulic performance with minimal power losses.

-

Safe for Hazardous Environments: Suitable for ATEX, API, or other explosion-proof requirements.

Applications of Magnetic Drive Pumps

Magnetic drive pumps are widely used in industries where safety, reliability, and fluid purity are essential:

-

Chemical Processing

-

Pharmaceutical and Biotech

-

Semiconductor Manufacturing

-

Oil & Gas

-

Water Treatment Plants

-

Food & Beverage

-

Pulp & Paper

-

Plating and Electrolysis Systems