Sintered Silicon Carbide (SSiC): Redefining Excellence in Advanced Ceramics

In the intricate tapestry of advanced ceramics, Sintered Silicon Carbide (SSiC) emerges as a material of unparalleled distinction. Renowned for its extraordinary performance attributes, SSiC is the epitome of precision engineering, embodying the perfect balance of strength, durability, and resilience. This blog explores the unique synthesis, outstanding properties, and multifarious applications of SSiC, underscoring its indispensable role in contemporary industry.

The Science Behind SSiC

Sintered Silicon Carbide is fabricated through a rigorous sintering process, wherein high-purity silicon carbide powders are compacted and subjected to extreme temperatures in a controlled environment. Unlike Reaction Bonded Silicon Carbide, SSiC achieves its density without the addition of free silicon, resulting in a material with superior purity and homogeneity. This intricate process enhances its structural integrity and optimizes its physical and chemical properties.

Defining Attributes of SSiC

Unrivaled Mechanical Strength

SSiC boasts exceptional hardness and fracture toughness, rendering it highly resistant to wear and mechanical deformation. This property ensures long-term reliability, even in the harshest operational conditions.

Superior Thermal Performance

With a high thermal conductivity and minimal thermal expansion, SSiC demonstrates excellent resistance to thermal shock. It retains its mechanical stability across a broad temperature spectrum, making it indispensable in high-heat environments.

Outstanding Chemical Resistance

SSiC’s chemical inertness to a wide array of corrosive substances—including strong acids, alkalis, and oxidizing agents—extends its applicability to chemically aggressive domains.

Exceptional Dimensional Stability

The sintering process ensures a material with minimal porosity and precise dimensions, reducing the need for secondary machining and enhancing its suitability for high-precision applications.

Applications Across Diverse Industries

The versatility of Sintered Silicon Carbide positions it as a cornerstone material in numerous cutting-edge sectors:

Aerospace: In aerospace applications, SSiC is leveraged for its lightweight yet robust nature in critical components such as turbine blades and thermal shielding systems.

Semiconductor Manufacturing: SSiC’s purity and thermal stability make it indispensable for wafer processing equipment, ensuring precision and consistency in microelectronics fabrication.

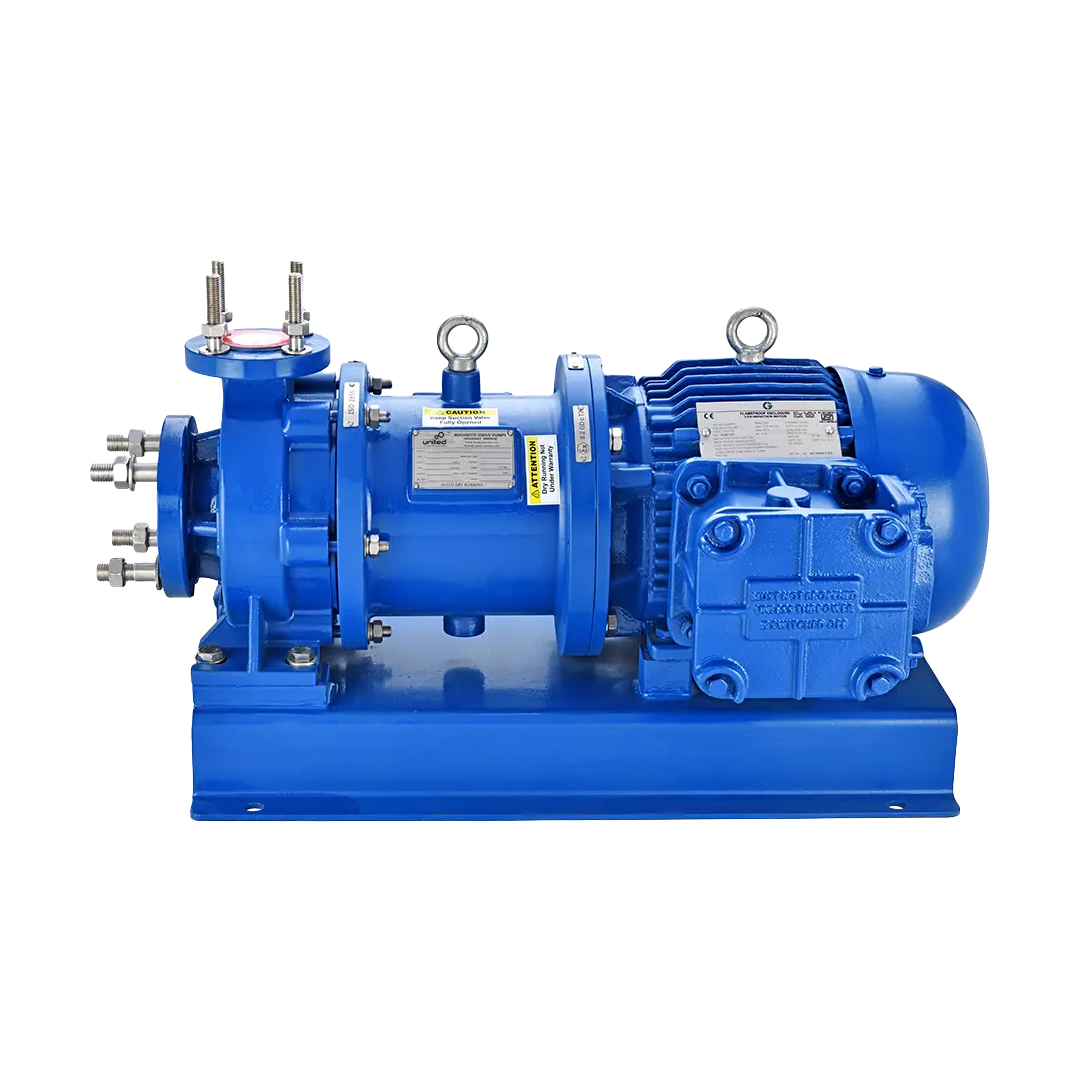

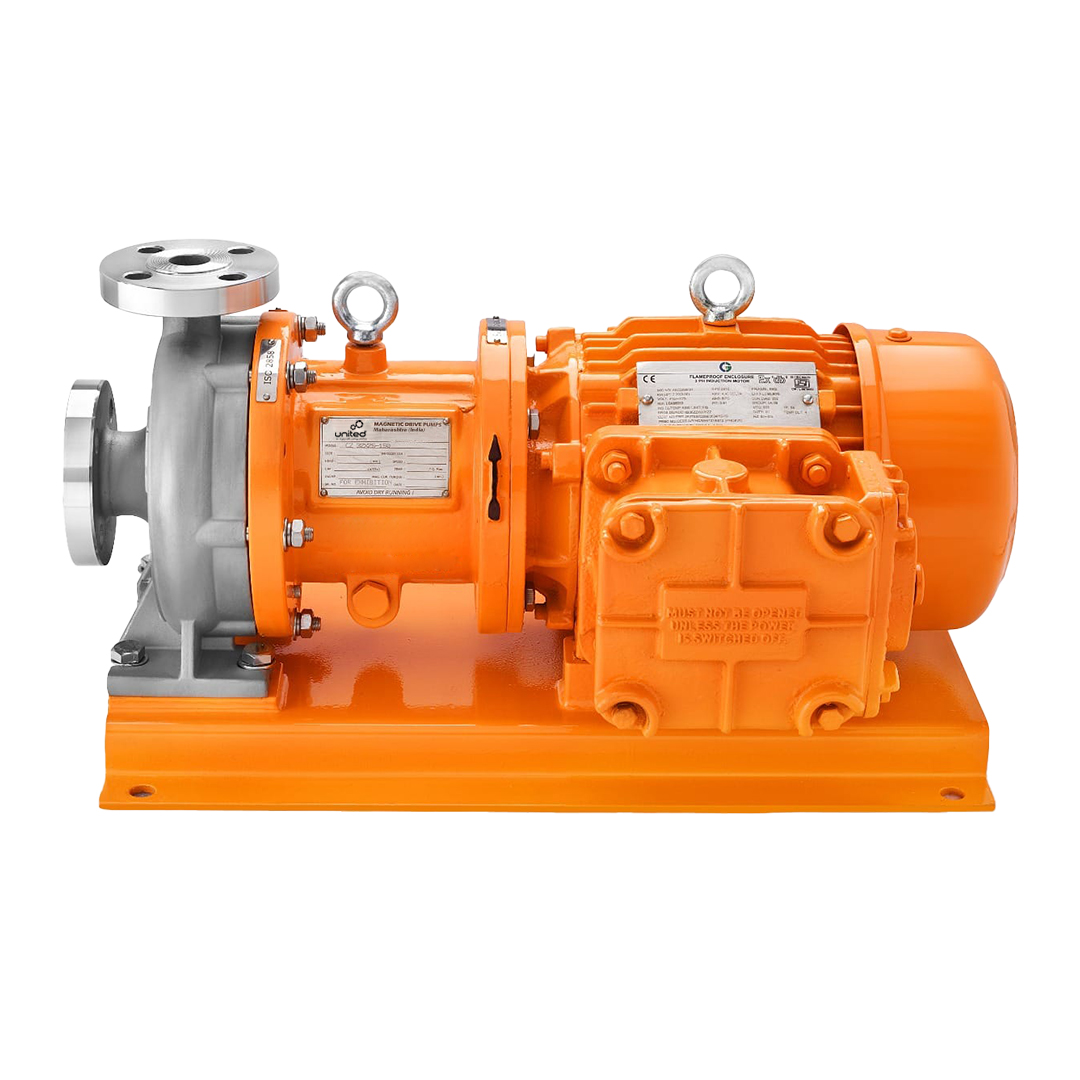

Chemical Processing: The material’s resilience against corrosive agents is harnessed in the construction of pumps, valves, and heat exchangers for chemical plants.

Energy Production: In power generation and renewable energy systems, SSiC components excel in handling extreme thermal and mechanical stresses, enhancing system efficiency and durability.

Medical Technology: SSiC’s biocompatibility and high wear resistance make it an ideal candidate for medical implants and surgical instruments, ensuring longevity and reliability in critical healthcare applications.

A Vanguard Material for Tomorrow’s Challenges

As industries evolve towards higher standards of efficiency and sustainability, Sintered Silicon Carbide remains a vital enabler of progress. Its ability to perform impeccably under extreme conditions, coupled with its versatility, establishes it as a pivotal material in addressing contemporary engineering challenges.

Conclusion

Sintered Silicon Carbide is more than an advanced ceramic; it is a manifestation of technological mastery and innovation. Its exceptional properties and diverse applications position it as a keystone material in the advancement of modern industry. For organizations seeking unmatched performance and reliability, SSiC offers a solution that transcends conventional boundaries. Embracing SSiC is not merely an investment in superior material science but a commitment to a future shaped by excellence and ingenuity.