Tungsten Carbide (Nickel Bonded) is a revolutionary material that combines the unparalleled hardness of tungsten carbide with the corrosion resistance and durability of nickel. This powerful combination creates a material that is ideal for demanding industrial applications where extreme wear, impact, and corrosion resistance are paramount.

Key Features of Tungsten Carbide (Nickel Bonded):

1. Exceptional Hardness: Tungsten carbide provides a hardness level that can withstand extreme abrasive conditions, making it a preferred choice for components exposed to high wear and tear.

2. Corrosion Resistance: The nickel binder enhances resistance to corrosive environments, ensuring long-lasting performance in harsh conditions, including exposure to chemicals and moisture.

3. High Wear Resistance: The material’s robust structure ensures minimal wear, even under heavy mechanical stress, reducing maintenance costs and downtime.

4. Thermal Stability: It maintains its mechanical properties even at high temperatures, making it ideal for high-temperature applications.

5. Versatility: Available in various grades and shapes, Tungsten Carbide (Nickel Bonded) can be tailored to specific industrial requirements.

Applications:

Due to its exceptional properties, Tungsten Carbide (Nickel Bonded) finds use in a wide range of industries:

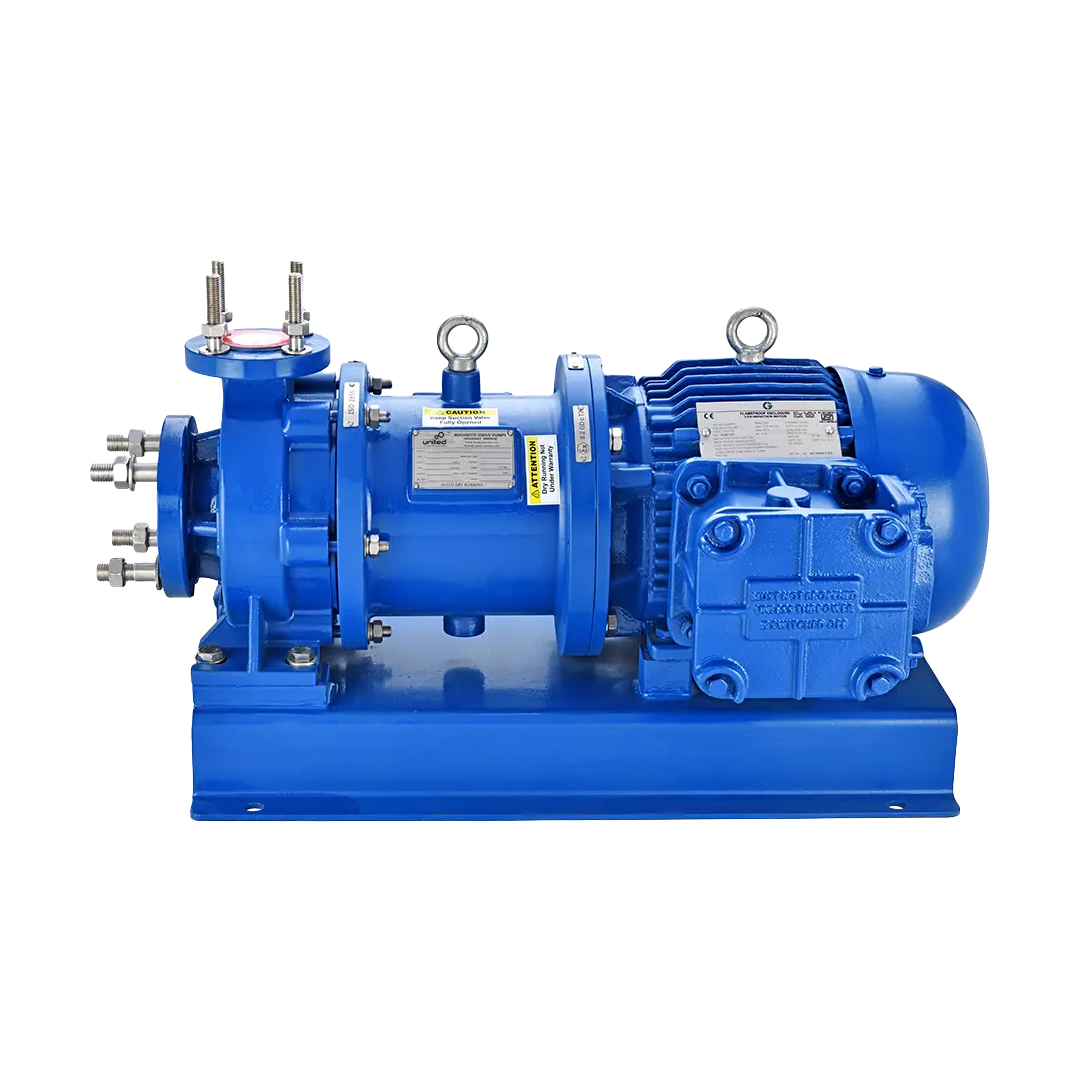

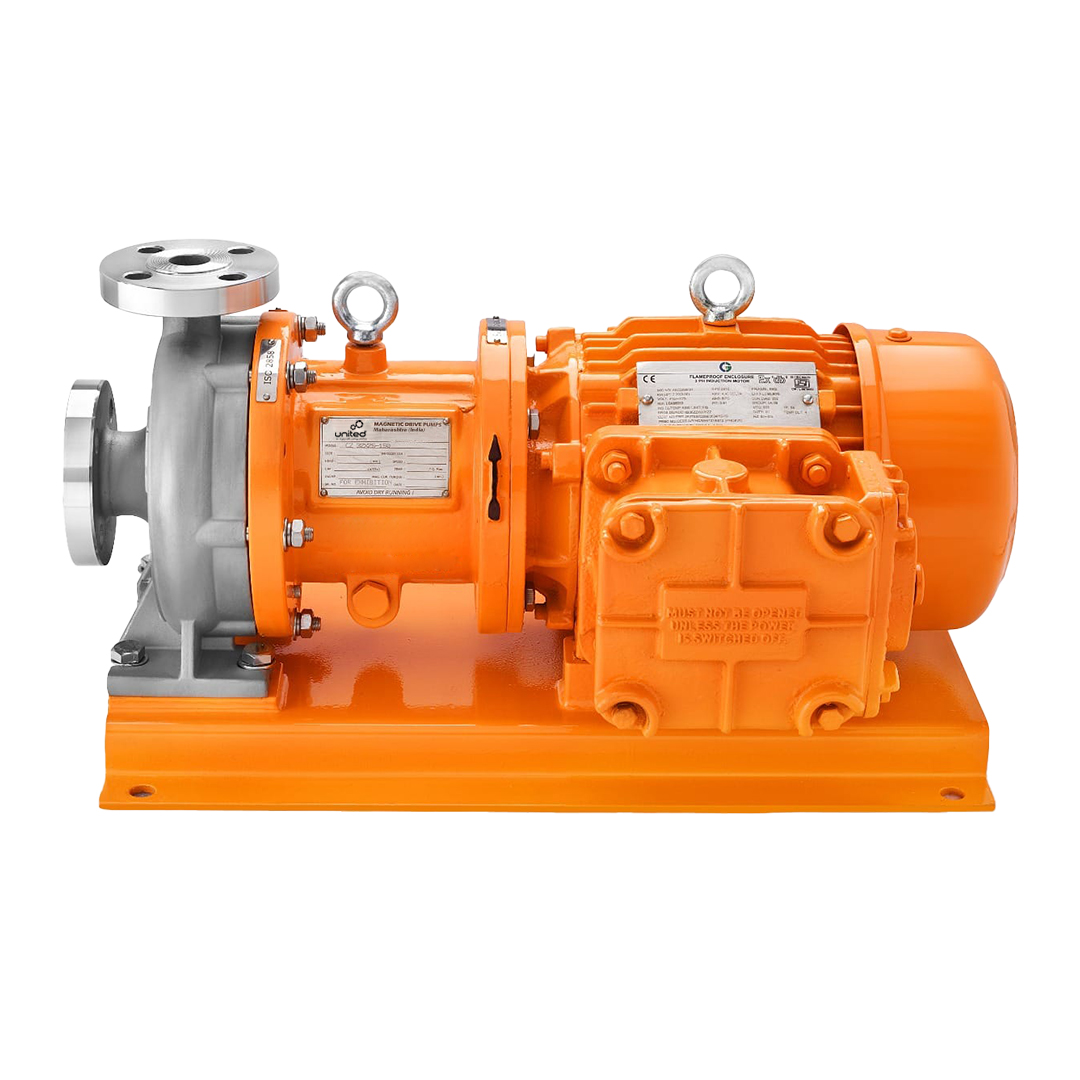

– Mechanical Seals: Its corrosion resistance and durability make it a key material in manufacturing seals for pumps and compressors.

– Aerospace and Automotive: Utilized in high-performance components that require wear and impact resistance.

– Oil and Gas Industry: Essential for drilling tools and wear-resistant parts operating in harsh environments.

– Mining and Construction: Ideal for cutting tools, drill bits, and wear plates.

– Precision Engineering: Perfect for making dies, punches, and other high-precision tools.

Why Choose Tungsten Carbide (Nickel Bonded)?

Tungsten Carbide (Nickel Bonded) stands out as a versatile and dependable material, capable of enhancing the performance and reliability of critical industrial components. Its superior hardness, coupled with excellent corrosion and wear resistance, ensures reduced operational costs and extended component life.